Nafitec™ functional inorganic nanoparticle immobilization technology

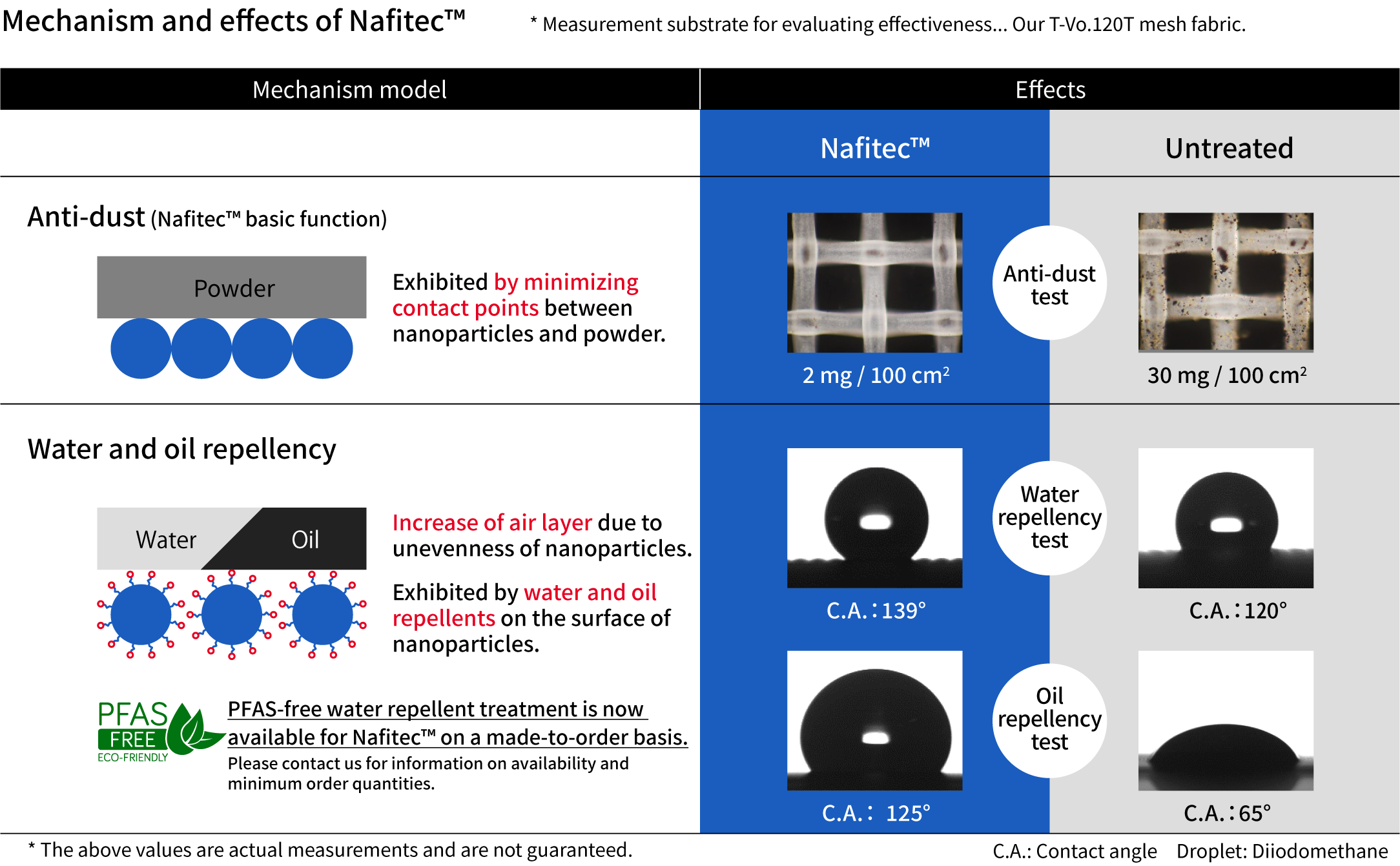

Mechanism and effects of Nafitec™

nafitec

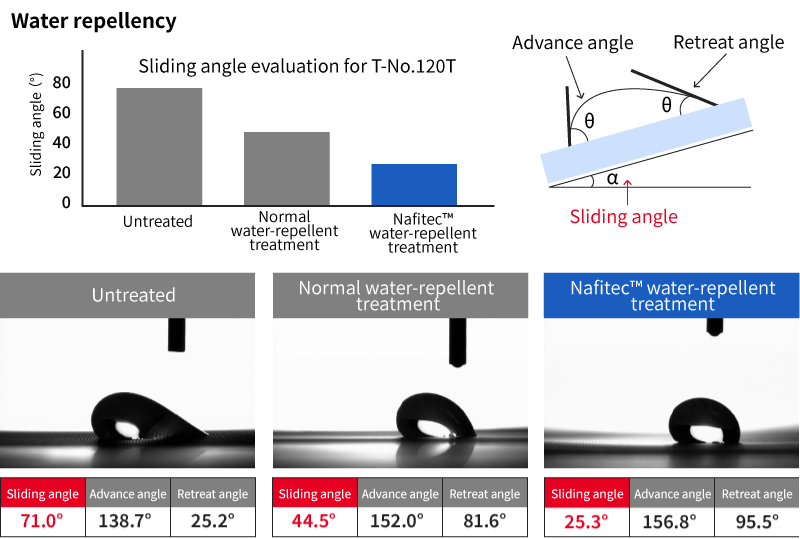

Sliding angle evaluation for Nafitec™

Test method

A drop of liquid (water) was dropped onto the mesh surface, and the angle at which the drop slides down (sliding angle) was measured when the mesh was tilted.

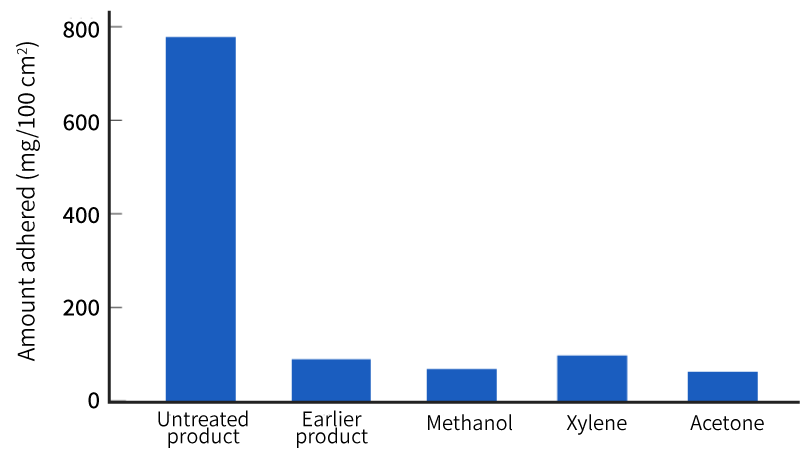

Chemical resistance of Nafitec™

Solvent resistance evaluation of Nafitec™

Test powder:Silver powder

Test method:

10 cm-square pieces cut out from a Nafitec™-treated product were dipped in each solvent, left at room temperature for 24 hours, and dried in a dryer for 1 hour.

Then, adhesion of the silver powder was checked along with an untreated product and earlier Nafitec™ product.

View the video on the effects of Nafitec™

Anti-dust function of Nafitec™

- See how it works -

Compare how much the anti-dust function of the same mesh differs between Nafitec™ -treated and untreated products.

Nafitec™ water-repellent treatment

- Watch rolling water ! -

What is the Nafitec™ water-repellent treatment ? Compare untreated and Nafitec™ water repellent-treated products.

We accept processing contracts.

If you are interested in Nafitec™, please feel free to contact us.

Related documents

Did you find what you were looking for?

Please feel free to contact us if you have any questions or concerns about sieve mesh clogging.

Our staff with extensive experience will bring your ideas to fruition.