Acoustic Mesh

Materials and Processing

acoustic-applicationsMaterials and processing for acoustic mesh

NBC Meshtec can help you with issues related to mesh for audio and electronic devices, including the selection of materials and processing methods. We will propose the most suitable solution for you, so please feel free to contact us. Our acoustic mesh is used in and contributes to communication devices such as smartphones, audio devices such as earphones and headphones, in-vehicle devices, and game devices.

Materials

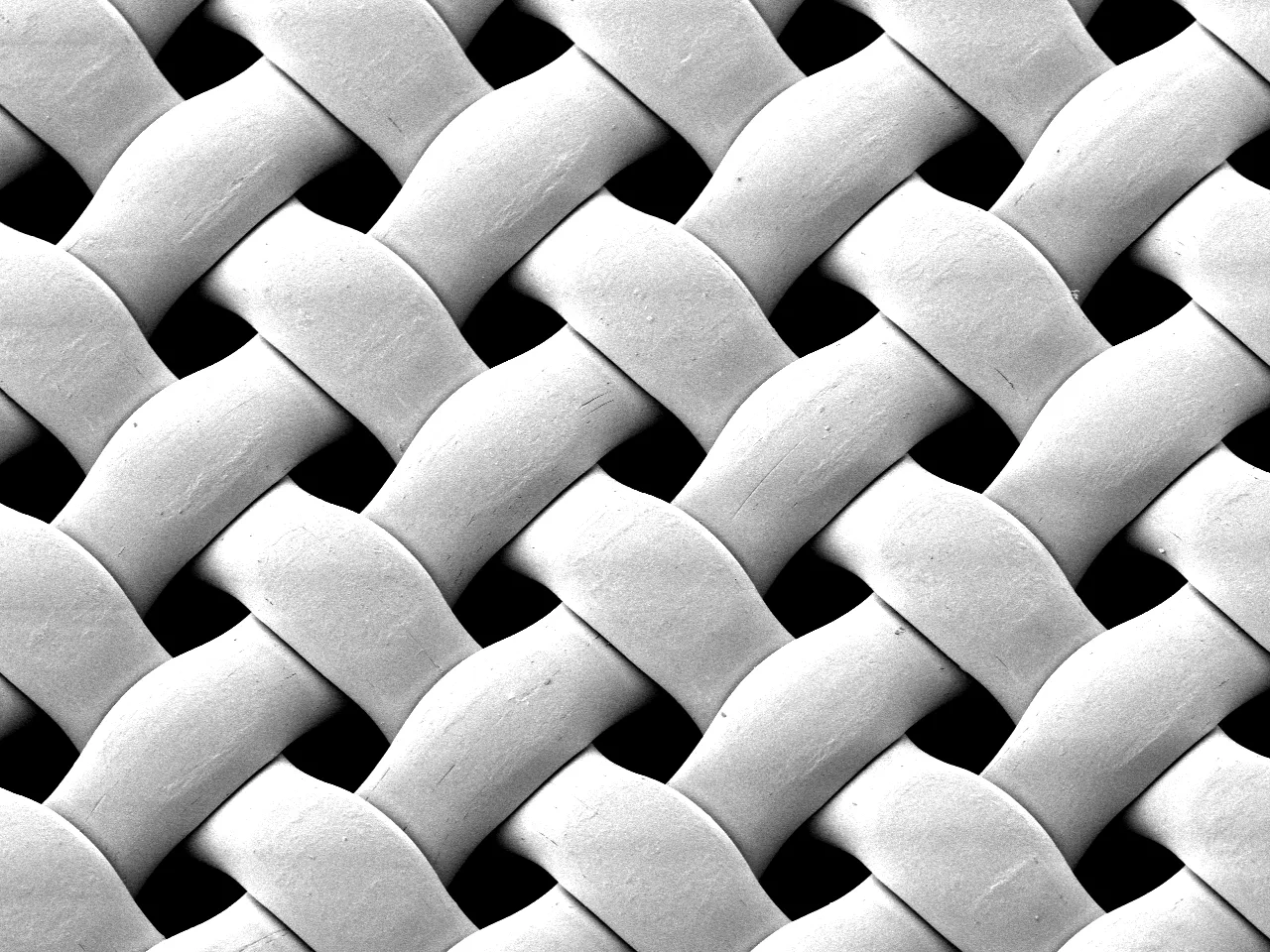

Polyester (PET) mesh

Polyester (PET) mesh

Various meshes with different wire diameters are available, and products with ultra-fine wires of 19 μm in diameter are also in the lineup.

The opening (OP) can be reduced with the same airflow resistance, resulting in a higher anti-dust effect.

This high-performance mesh prevents small dust particles from entering but allows sound to pass through.

High-performance liquid crystal polymer (LCP) mesh

This is a mesh made of liquid crystal polymer (LCP), a highly functional material, with high strength, low elongation, low water absorption, heat resistance, chemical resistance, and excellent vibration damping properties.

It is also used in screen printing applications that require high precision.

Other synthetic fiber mesh

Nylon (PA), polyethylene (PE), and polypropylene (PP) are also available.

In addition to LCP, we also offer PPS and other super engineering plastics with high heat resistance.

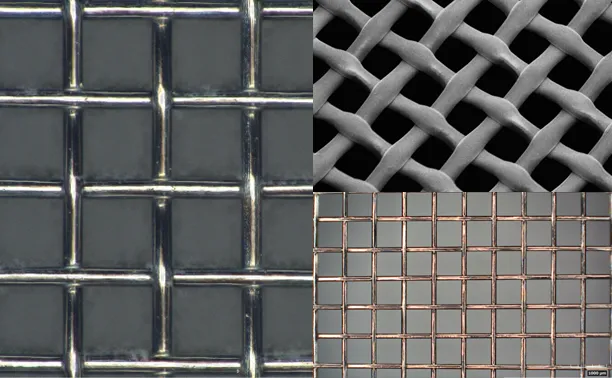

Metal mesh

Stainless steel (SUS), Tungsten (W), etc. are also available.

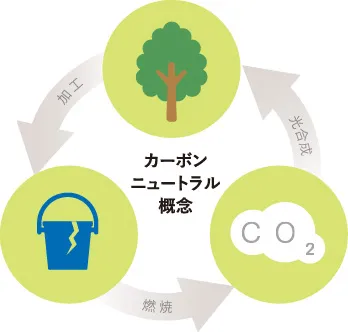

Biomass plastic mesh

We also offer environmentally friendly biomass and recycled materials (under development).

Sustainability Initiatives

Processing

Primary processing

General-purpose processing

Surface treatment techniques for mesh (primary processing) are introduced here.

Various treatments can be applied to the mesh surface, such as dyeing, adding water-repellent functions, etc.

- Dyeing

- Water repellent treatment

- Vapor deposition treatment, etc.

- Fluorine-free, REACH and RoHS compliant

High-performance anti-dust and water repellent techniques

●What is NafitecTM?

It is our proprietary technology for immobilizing functional inorganic nanoparticles on the surface of substrates. This technology makes it possible to add advanced functions such as adhesion control and water and oil repellency.

High-performance antiviral and antibacterial technology

●What is CufitecTM antiviral and antibacterial technology?

It is our proprietary antiviral and antibacterial technology based on monovalent copper compound nanoparticles. It can be processed on a variety of materials and used for a wide range of applications.

CufitecTM is not effective against all viruses and bacteria.

Secondary processing

Secondary processing techniques to process the shape of the mesh are introduced here.

We can process the mesh into your desired shape by slitting, punching, or other methods.

- Slitting

- Punching

- Integrated molding

Development Support

Related documents

Did you find what you were looking for?

Please feel free to contact us if you have any questions or concerns about acoustic mesh.

Our staff with extensive experience will bring your ideas to fruition.