Custom-Made Process & Support Information

Quality Control

mf-supportReliable quality control system

Our quality control policy states that "products are alive," and we ensure through quality control that no abnormality, no matter how small, is overlooked, from incoming material inspections to product shipment, so that we can earn the appreciation and trust of our customers.

About the inspection process

■ In-process inspection

During the manufacturing process, NBC Meshtec's own certified inspectors conduct on-site inspections at the plant.

We utilize a wide variety of methods to control product quality, including monitoring data and parameters, checking the appearance of molded products, and evaluating quality using measuring and testing equipment.

■ Incoming inspection

Incoming inspections are conducted on critical quality items and specifications of materials, as well as the appearance and dimensions of molded products.

If nonconforming products are found, prompt action and countermeasures will be taken.

■ Final inspection

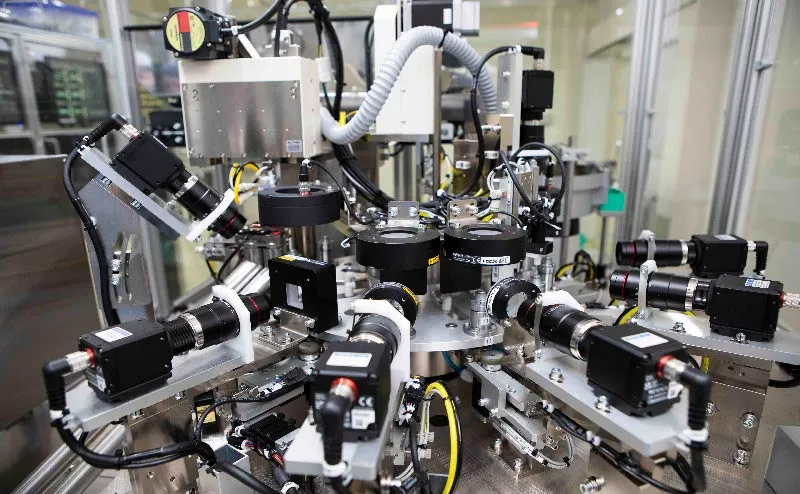

After the product has passed through the production line, a final quality evaluation is conducted.

Automatic inspection equipment using high-precision cameras and skilled visual inspections ensure that the product complies with required specifications.

These inspection systems enable us to provide products that our customers can use with confidence.

To avoid making defective products

In the product development and prototype stages, we make proposals to our customers based on our long-cultivated expertise in the production of molded products.

In the prototype stage, we thoroughly eliminate defects, aiming for a manufacturing process that neither produces defective products during mass production nor passes defective products on to the next process.

In the manufacturing process, we use a production system that minimizes human error and its impact on quality by using our independently developed automatic machines to achieve high production efficiency and stable quality, as well as to improve the consistency and precision of work.

In the unlikely event of a defect, we quickly identify the cause and provide feedback to the production process.

Thorough analysis of the causes of defective products and implementation of remedial measures will prevent similar defects from occurring.

These efforts prevent defects in daily production, maintain stable quality, and realize low-cost manufacturing.

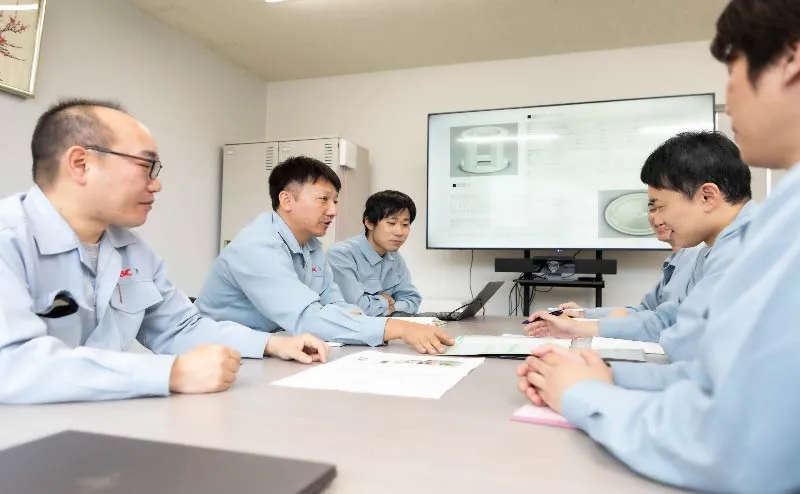

Review meeting before transition to mass production

Prior to the transition to mass production of a product, Review Meetings are held periodically with the relevant departments to confirm the quality of the product. We share product specifications, manufacturing procedures, quality inspection methods and standards, quality control methods, and other factors that affect quality to minimize the risk of defects after the transition to mass production.