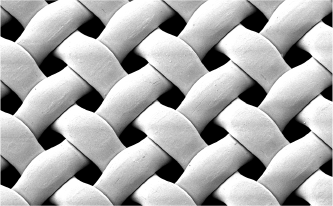

Mesh cloths for screen printing

Process of screen making

screen-printing-applicationsThe process of making a screen plate used in screen printing is as follows.

01Preparation

Determine the size of the plate frame according to the size of the printed matter.

Plate frames are available in aluminum, cast metal, and wood frames.

In addition, select the mesh according to the mesh material, mesh count, printing usage, etc.

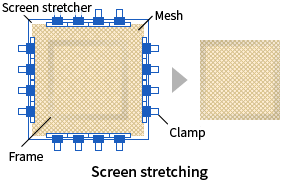

01Screen stretching

Screen stretching is the process of stretching mesh over the frame. This is done using a screen stretcher.

First, place the frame on the screen stretcher, cut the mesh to a size that the clamp can grip, insert the screen in the clamp, and apply tension. Once the set tension is reached, leave it for a few minutes, then apply adhesive to secure it to the frame. When the adhesive is completely dry, detach to complete the process.

01Stencil cleaning

Clean the stencil using a special detergent and plate washer to remove dust, dirt, oil, grease, etc. from the stencil. Failure to perform this cleaning will result in poor adhesion of the photosensitive emulsion, which is the next step in the process.

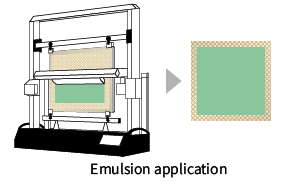

01Coating of emulsion

This is the process of coating the mesh with emulsion.

There are two methods of coating emulsion: direct and indirect. The direct method uses a bucket to apply liquid photosensitive resin. In the indirect method, a slow-acting emulsion membrane formed on a support film with excellent flatness is attached to the plate, and the emulsion membrane is formed by peeling off the support film.

This section describes the direct method.

Apply the coating with a photosensitive emulsion applicator or by hand.

Determine the bucket according to the size of the frame and feed the emulsion. First, thinly apply the emulsion to the reverse side (opposite the printing surface) to fill the screen openings, then repeat coating and drying until the desired film thickness is achieved. After the emulsion coating, measure the thickness and allow it to dry thoroughly.

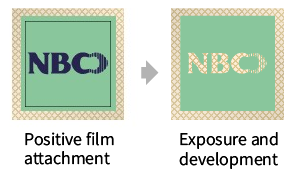

01Exposure and development

Attach a positive film to the emulsion-coated plate and expose it. The exposure amount is determined by the emulsion thickness and the performance of the photosensitive emulsion filling the openings. Underexposure causes the emulsion to run off during water development, resulting in jagged lines. Conversely, overexposure causes too much emulsion to adhere to the screen threads, resulting in crushed fine lines and narrow widths between lines. After exposure, develop it with water and dry it.

01Inspection and pinhole countermeasures

Finally, carry out inspection on the light table to check for pinholes, and repair any detected pinholes with a photosensitizer. For precision printing that does not involve plate transfer or reprinting, adhesives, paints, and inks can be used as substitutes.

Related documents

Did you find what you were looking for?

If you have any concerns or questions about mesh for screen printing, please feel free to contact NBC Meshtech.

We will introduce you to a distributor based on the application of the mesh and your desired region, and make your requests a reality.