Mesh cloth for screen printing

Metal Series

monofilament-meshMetal mesh suitable for printing electronic components, etc.

The lineup ranges from standard products to ultra-high strength products.

Features

Application examples

Precision printing of solar cell electrodes, electronic substrates (PWB, FPC, LTCC, HTCC, etc.), electronic components (MLCC, resistors, inductors), membrane switches, etc.

〇 PWB (Printed Wiring Board)

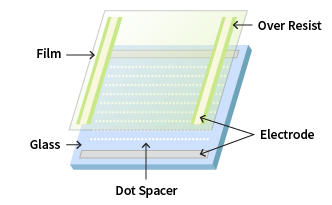

A printed board with wiring before components are mounted FPC (Flexible Printed Circuit) --- A substrate with electrical circuits formed on a base material consisting of an insulating base film and conductive foil laminated together.

〇 LTCC (Low Temperature Co-fired Ceramics)

A multilayer ceramic substrate consisting of a low-resistance conductor and a ceramic base material formed in one piece.

〇 HTCC (High Temperature Co-fired Ceramics Substrate)

A multilayer ceramic substrate with superior dielectric strength and thermal conductivity compared to TCC.

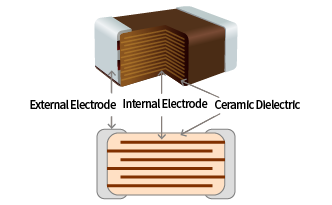

〇 MLCC (Multi-Layer Ceramic Capacitor)

An electronic component that repeats temporary accumulation and release of electricity, absorbs noise contained in signals, extracts signals of a certain frequency, cuts direct current, and passes only alternating current.

〇 Resistor

An electronic component that regulates current, extracts the required voltage, and converts electrical energy into heat.

〇 Inductor

An electronic component that generates an electromotive force in the direction that blocks fluctuating currents and stores electrical energy as magnetic energy, allowing DC signals to pass through but not high frequency signals.

Product specifications

| materials | Stainless steel(SUS)Tungsten(W) |

|---|---|

| Mesh count | 120 to 730 per inch |

| Wire diameter | 11 µm to 80 µm |

| Application examples | |

| Material of mesh | |

| Processing methods | |

| Target material | |

| Features | |

| Applications | |

| Resin materials |

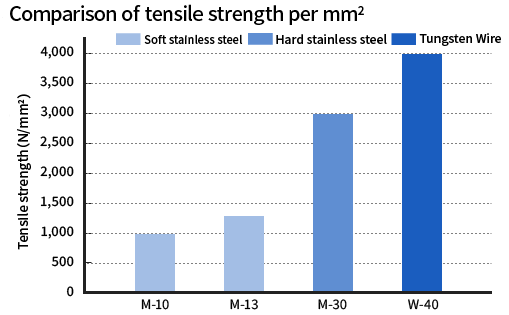

Comparison of properties

| Tensil strength |

|---|

| emulsion adhesion |

| antistatic capability |

The Japanese electronic component industry, which faces increasingly stringent quality and precision requirements, utilizes world-class screen printing technology to support the global electronic component, automotive, and solar panel industries. In order to further improve the quality of these industries, the Metal Series offers a lineup of five different products categorized by application and performance.

| Material | Product name | Tensile strength (N/mm²) |

Mesh count (per inch) |

Wire diameter (µm) |

Features | Application examples |

|---|---|---|---|---|---|---|

| Stainless steel | M-10 | 1,000 | 120~500 | 80~19 | This is a standard type and widely used series. The lineup ranges from low count mesh to high count mesh to meet various requirements. |

|

| M-13 | 1,300 | 325~730 | 23~13 | The strength is approximately 30% higher than that of the standard type, compensating for the lack of strength that is an issue with high count mesh products. It can also be used for high-precision printing required for MLCC, LTCC, precision electronic components, etc. |

|

|

| M-30 | 3,000 | 250~480 | 20~11 | High-strength type series, suitable for precision electronic components such as MLCC and LTCC. Printing with “high definition and high positional accuracy" can be achieved. The high open ratio ensures good permeability even with high-viscosity pastes, making it suitable for solar cell electrode printing and other applications (3 times the tensile strength of M-10). |

|

|

| HDM | - | 200~325 | 40~28 | HDM (Heavy Deposit Mesh) Series is a screen developed for thicker special thick-film printing applications. |

|

|

| Tungsten | W-40 | 4,000 | 325~480 | 16~11 | This is a material with ultra-high strength and enables ultra-high precision printing. It can meet the ever-increasing demand for MLCC, LTCC, and precision electronic components with "high definition + high positional accuracy + high durability + high paste permeability," realizing the next generation of screen printing (4 times the tensile strength of M-10). |

|

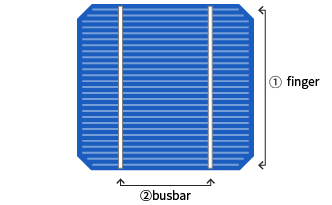

Solar cell finger electrode・Solar cell busbar electrode

Finger Electrode: Collects the current generated by the power generation element and supplies it to the busbar electrode. Currently, the miniaturization of finger electrodes is progressing to increase the power generation efficiency of solar cells.

Busbar Electrode: Collects the DC current generated by the finger electrodes. To prevent loss of the generated current, a metal mesh that can be uniformly printed is required.

Chip capacitor

Along with its property of storing electric charge, the capacitor has the important function of passing alternating current without passing direct current. Chip capacitors are suitable for miniaturization of circuit boards due to their smaller component size and compatibility with flow soldering. This requires a high-strength metal mesh, as minor misalignments can cause major problems.

Related documents

Did you find what you were looking for?

If you have any concerns or questions about mesh for screen printing, please feel free to contact NBC Meshtech.

We will introduce you to a distributor based on the application of the mesh and your desired region, and make your requests a reality.