Search by Category

Mesh cloths for screen printing

screen-printing-applicationsNBC Meshtec’s mesh cloths for screen printing

We continue refining our weaving technology of mesh.

We consistently provide high quality mesh for the future of manufacturing, driven by the ever evolving technology of the manufacturing industry and screen printing.

In addition to developing and producing mesh, we are also working on improving screen printing technology and printing accuracy.

1. High tech, highly durable mesh cloths compatible with small, high definition products

2. Active development of new materials

3. System capable of promptly responding to customer needs

4. Qualitative improvement of services by exploiting our know-how cultivated over the 90 years since out establishment

5. Mesh technology adopted all over the world

Features

Delivering extremely safe products

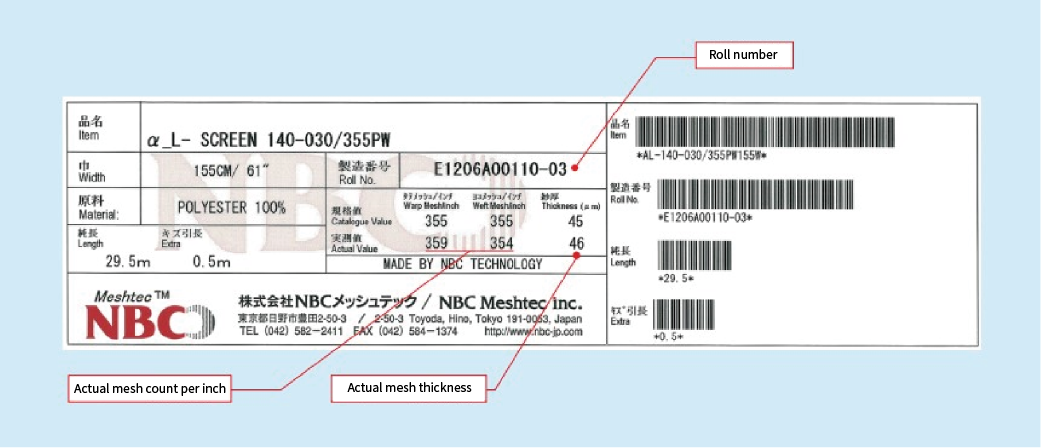

Our mesh products are shipped with a product inspection tag attached to each roll. The information indicated on this product tag ensures traceability.

Products

Product Lineup

The performance required of today’s screen printing is higher "dimensional accuracy," "durability," and "resolution.”

NBC Meshtec provides high-quality mesh cloth to meet your needs in a wide variety of materials for different applications, including polyester (PET), nylon (PA), and stainless steel (SUS).

Applications/Adoption Examples

Application examples

Client

Adoption Examples

Support Information

Related documents

Did you find what you were looking for?

If you have any concerns or questions about mesh for screen printing, please feel free to contact NBC Meshtech.

We will introduce you to a distributor based on the application of the mesh and your desired region, and make your requests a reality.